Technologies having Potential for Commercialization

Salient Features:

- Weight recording system – Load Cells for Seed cotton, lint and cottonseed

- Specially designed tray to collect lint and cottonseed

- Inbuilt Human Machine Interface (HMI) in GOC- PLC Setup with software programme

- Electronic display unit: Four digital indicators showing weight of seed cotton, lint, cottonseed and GP

- Display GP values in Percentage

- Compatible with PC and provision for data gathering through micro SD card

Salient Features

- Beater Type: Paddle type beaters

- Input Capacity: 6-8 Q/h (Raw kawadi)

- Output Capacity: 5-6 Q/h

- Efficiency: 80%

- Improvement in Lint Recovery: 18% more than conventional practice

- Overall Dimensions: 3.5 x 1.5 x 1 m

- Weight: 500 kg

- Power: 5 HP

Description and Salient Features

A cotton based high performance wound dressing pad with better absorbency and antimicrobial property has been developed by the institute. High absorbency is produced using Cotton hybrid non-woven materials and antimicrobial property using nano-silver. The developed cotton wound dressing pad helps the wound remain moist with exudates but not macerated, free from infection and improves the wound dressing duration, with cost-effectiveness. The nanosilver based wound dressing showed excellent activity with more than 99.00 % reduction for both Gram-negative and Gram-positive bacteria as per AATCC TM 100: 2019 standard test method. The unique processing technology also enhanced the absorbency of the wound dressing pad by 33%.

Description and Salient Features of Technology

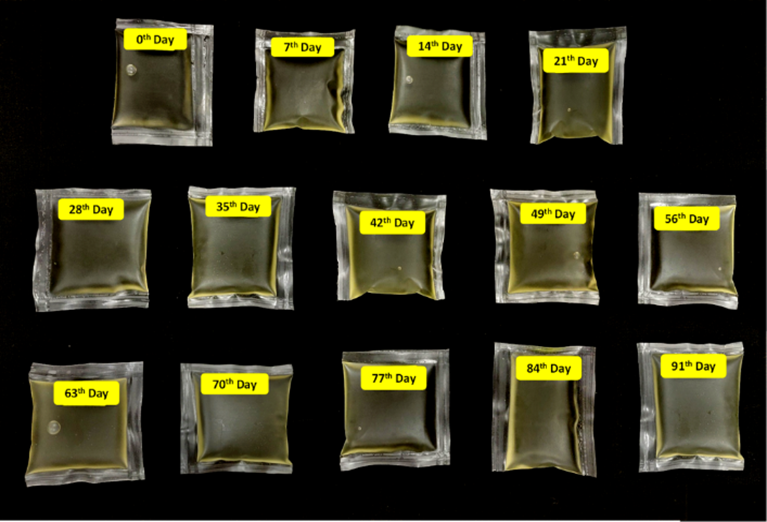

Nano-cellulose (NC) synthesized from cotton linters was used as a green filler in starch matrix to obtain composite films with improved functionality. The films were prepared using solvent casting method. Film formulation was optimized using a response surface methodology (RSM) tool. Easily heat sealable stand-alone films with average 100 μm thicknesses were prepared using the optimized formulation.

- The incorporation of NC (0.89%) to starch polymer yielded films with improved mechanical strength, flexibility and water vapour barrier.

- Tensile strength (TS), elongation at break (EB), water vapour permeability (WVP), bursting strength (BS) and tearing strength (TeS) of the films was found to be 8.92 MPa, 41.92%, 7.07x10-10g/m.s.Pa, 556 kPa, 354 mN respectively.

- The films presented high effectiveness in keeping the quality of edible oil for more than 3 months at ambient storage conditions.

- Soil burial test showed complete degradation of films within four weeks.

- These NC impregnated starch films have promising potential as an eco-friendly packaging material alternative to synthetic polymers.

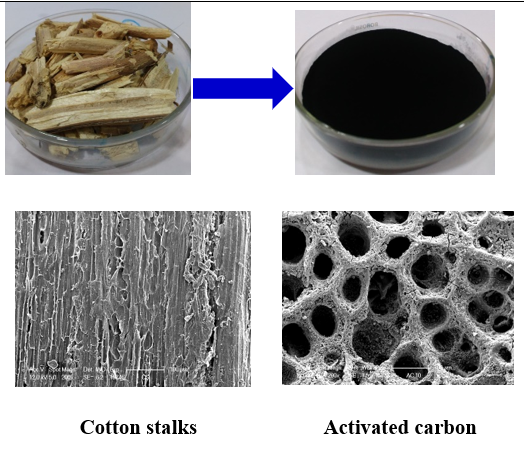

Salient Features

- Surface area (BET) : 1010m2/g

- Average pore radius : 2.67808e+01Å

- Total pore volume : 1.353e+00 cc/g

- Bulk density : 0.4566 g/mL

- pHpzc : 4.6

Salient Features

Engineered Cotton Face Mask | Particle Filtration Efficiency (%) | Air resistance (Pa/cm2 ) |

3 Layer | 41.17 | 19.91 |

4 Layer | 49.82 | 27.80 |

5 Layer | 51.93 | 34.18 |

Description and Salient Features of Technology

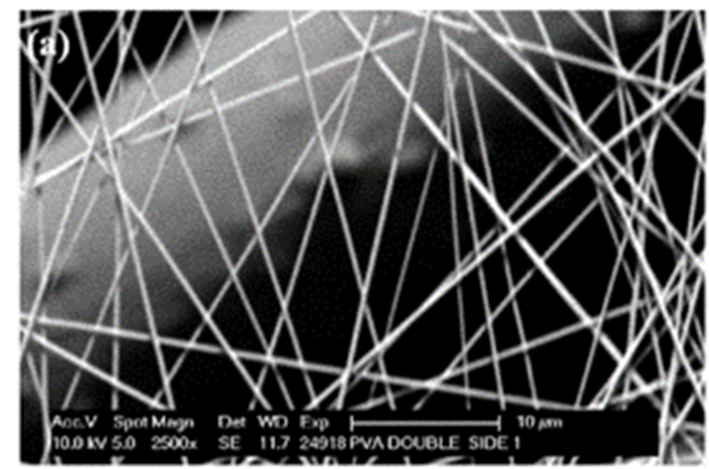

Electro-spun nano-fibre based replaceable cartridge was developed for use in cotton fabric face masks. The aligned electro-spun nano-fibre coated nonwoven fabric is sandwiched with two layers of uncoated nonwoven fabric, which can be inserted within the multi-layer face mask as a replaceable filter media. They are made with biodegradable polymer electro-spun nano-fibres and the produced nano-fibre diameter is around 100 to 300 nm. Due to finer fibre diameter and increased surface area, its effect begins to play an important role in the filter of the most penetrating aerosol particles. Also, they allow more air to pass within the substrate; so it enhances breathability.

Description and Salient Features of Technology

Uniform electrospinning mat production is one of the major bottleneck in electrospinning process. To overcome this, Multi- phase electrospinning setup was designed and fabricated. It will enhance the electrical field distribution and even solution feeding to all the needles. The customized design has many adjustments and automations like multi-axial arrangements with different nozzle geometry, angle change and automated linear motion stages and multiple parallel needles to increase the production by enhancing the electrical field distribution and even solution feeding to all the needles. This can be used for different polymer and solvent systems. The motion and speed can be controlled through display. It has the advantage of multi-layer fibre forming with even mat production throughout 360 degree.

Description and Salient Features

ICAR-CIRCOT has developed an accelerated process for composting using microbes for the preparation of bio-enriched compost from cotton stalks. The chipped cotton stalks are treated with CIRCOT developed microbial consortia to accelerate the composting process. Good quality compost is prepared in 45 and 60 days, respectively from wet and dry cotton stalks. In comparison, the compost from dry - and wet - untreated cotton stalks requires 90 and 60 days, respectively. Thus, 15- 30 days can be saved for the preparation of compost from wet and dry cotton stalks. The nutrient (NPK) level of cotton stalks compost is three times higher than farm yard manure (FYM). It is found that the seed cotton yield of cotton crop with the use of 5 t of cotton compost as modified integrated nutrient (NPK) management is at par with present integrated nutrient management with 12.5 t of farm yard manure. On-farm use of bio-waste of cotton stalks can save precious money of farmers by use of this technology.

- Microbial consortia is developed by ICAR-CIRCOT

- Yield of compost is 800 kg per tonne of cotton stalk

- Bio-enriched compost made out of cotton stalks which has higher NPK content (1.43:0.78:0.82) as compared to farm yard manure (0.5:0.2:0.5).

- Duration of composting is 45 days for wet and 60 days for dry cotton stalks

Description and Salient Features

Lack of viable logistic model for supply of chipped cotton stalks to the industries was the cause for non - utilization of cotton stalks for industrial applications. Traditional method of uprooting cotton stalks with a traditional tool (chimta) was very tedious and labour intensive process. Hence, it was not viable for supply of cotton stalks for any industrial use. Therefore, viable logistics model have been developed for supply of cotton stalks for pelleting, briquetting and power generation industries. Developed model comprises of uprooting of cotton stalk from field using a tractor operated V-type up-rooter followed by sun drying and shredding by a tractor operated shredder. Transportation of the chipped cotton stalk to the briquetting and pelleting plant within the radius of 50 km.

Description and Salient Features

Seed cotton is conventionally traded irrespective of its ginning percentage (GP) which is a major price deciding component. Seed cotton is traded by presuming GP of around 34% and accordingly prevalent Minimum Support Prices (MSP) are offered to farmers. However, some cotton varieties realize as high as 42% GP. The benefit obtained out of higher GP goes to the pocket of traders and farmers are deprived of this benefit. CIRCOT is insisting policy makers to include GP as one of the parameter for cotton grading and deciding MSP for cotton.

Hence, to promote GP based seed cotton trading, ICAR-CIRCOT launched a pilot project on lint based cotton trading to augment in doubling farmers’ income. It was a first of its kind innovative initiative in India. Under this pilot project, trading of seed cotton on the basis of lint realization or Ginning Percentage (GP) is promoted at APMC Market of Hinganghat (M.S.). At this facility, GP of cotton is determined on laboratory model ginning machines, developed and supplied by CIRCOT, before auction in APMC. This facility empower farmers to trade cotton based on GP and bargain with the ginners and traders accordingly.

Description and Salient Features

Cottons are being contaminated by wide range of impurities gathered during picking and post-harvest handling, till it reaches ginning industry. The quality of Indian cotton gets deteriorated because of contaminants both organic and inorganic. The cotton gets contaminated at various levels, viz. at farms, during transportation to farm house, storage, transportation to markets, at market yards and at ginning & pressing factories. Due to this problem of high contamination, Indian cotton is sold at discounted rates. Contamination represents a significant threat and element of cost to ginning and spinning mills, as it forces them to implement a range of costly methods to remove the contamination. To address this issue, ICAR-CIRCOT has developed and suggested appropriate best farm practices and post-harvest management practices to be followed to preserve the fiber quality and to prevent the contamination at the sources of contamination.

Institute has also developed a clean cotton picking kit comprising of cotton cloth head gear/scarf and cotton cloth bags for cotton picking, for filing picked cotton and for unloading picked cotton at the end of field after picking.

Description and Salient Features

This is an in-house technology developed by the institute through a revolving fund project. Since 1997, the institute is producing calibration cotton and supplying it to mills, research institutes and testing instrument manufacturers in the country. CIRCOT is the second institute in the world next to USDA to prepare the calibration cotton for textile testing. The standard reference material developed is used for calibration of the High-Volume Instruments used for fibre testing and is an import substitute for the USDA calibration cotton.

ICAR-CIRCOT is offering indigenously prepared reference material for calibration of HVI machine having quality characteristics similar to those of USDA calibration standards. Calibration cotton is supplied in a packet containing about 200g of fibres, uniquely coded and labelled with various important fibre properties like 2.5% span length, uniformity, micronaire, 3.2 mm gauge tenacity etc. It is expected that the inter packet variability in fibre properties be as low as possible so that the particular lot of reference material serves the need of many users simultaneously. Further, a user may ask for reference cotton with particular length or micronaire or strength value or their combination and as supplier CIRCOT is able to supply it from its available stock with minimum variation.

Description and Salient Features

ICAR-Central Institute for Research on Cotton Technology at Mumbai, has endeavoured to process coloured cotton which is a shorter staple length fibre that makes it more difficult to spin. Using Vaidehi 95 - a brown coloured hybrid developed by ICAR-Central Institute for Cotton Research at Nagpur, CIRCOT has spun the fibres into usable threads in its in-house spinning department, which is further processed to develop value added products such as Jackets, Handkerchiefs and Infant wears. Products from these naturally coloured cotton are 100% chemical free, non-allergic and has good colour stability. The fabric also has very high wash durability with inherent anti-microbial and UV protective properties. This Farm to Fabric conversion of naturally coloured cotton is pollution-free, eco-friendly, energy-efficient, cost-effective and nontoxic. ICAR-CIRCOT has developed Process Technology for development of Value Added Products from Naturally Coloured Cotton.

Description and Salient Features

A new salt free dyeing technology was developed using cationic polymer. By using the technology, cotton fabric was dyed with both Chloro triazine and vinyl sulphone based reactive dyes. The newly developed process provided similar dyeing shades as that of already developed one. The advantage of new process is that the total organioc carbon (TOC) and total nitrogen (TN) values of the effluent are 3 times lesser than the already developed one. Cotton has to be pre-treated with cationising chemical before dying. The pre-treated cotton can be dyed without the use of salt. Using salt free technology, 10 times reduction in the TDS of the effluent from 16000 to 1600 ppm, well below the pollution control board nor of 2100 ppm, is achieved. Due to less TDS, effluent treatment does not require installation of RO which can lead to cost effective ZLD process. CIRCOT has completed three scale-up trials for dyeing the cotton fabric using this technology at industrial level and produced cotton woven shirts and T-shirts. The developed process can be adopted at an industrial level without any modification of existing machinery sequence.

- Back to previous page

- |

-

Page last updated date:10-11-2025 10:44 AM