Quality Evaluation And Improvement Division (QEID)

The Quality Evaluation was one of the two divisions established at the initial stages of the Institute (then known as Technological Laboratory) in the year 1925. The main objective of the Division was to provide objective methods of tests to the cotton breeder for the estimation of quality of new strains of cotton. The division also conduct studies to investigate relationships between fibre properties of cotton and its spinning potential. During the early years of its existence, the Division has done considerableresearch to develop and standardise test methods and testing equipment. The Division, being a partner in All India Co-ordinated Research Project on Cotton (AICRP on Cotton), provided with guidance for developing strains with enhanced fibre attributes at every stage of breeding program. Apart from above, the Division is engaged in providing calibration cotton to the industries & machine manufacturers. The division has also contributed towards utilization of other natural fibres such as banana, ramie etc. The QEI Division is also extends its facilities to trade and industries by way of commercial testing and contributing towards the resource generation for the Institute. QEI Division is acting as bridge between farmers and industry.

Mandate

- To offer technological support to All India Co-ordinated Research Project on Cotton (AICRP on Cotton) in the areas of fibre, yarn and fabric quality evaluation.

- To develop and supply Standard Reference Materials (SRM) like Calibration Cotton.

- To develop new technologies in the areas of Instrumental Grading of fibre, yarn and fabric of cotton and other natural fibres and composites.

- To contribute in revenue generation through physical testing of textiles and function as a referral laboratory.

Head of Division

| Sr.No. | Name | Designation & Research Interest | Contact | Photo | |

|---|---|---|---|---|---|

| 1 | Dr. A. S. M. Raja | Principal Scientist (Textile Chemistry) Research Interest : Absorbent cotton, Chemical testing, Enzyme base textile processing, Garments,Innovative and sustainable dyeing and finishing process, Medical Textiles, Natural dyes etc |

Ext No. 401 | Raja[dot]ASM[at]icar[dot]org[dot]in |  |

Scientists

| Sr.No. | Name | Designation & Research Interest | Contact | Photo | |

|---|---|---|---|---|---|

| 1 | Dr. Jagajanantha | Senior Scientist (Textile chemistry) Research Interest : Dyeing, Printing, Finishing and Smart Textiles |

Ext No. 408, 417 | jagajanantha[dot]P[at]icar[dot]org[dot]in |  |

| 2 | Dr. Kirti Jalgaonkar | Senior Scientist (Agricultural Structures and Process Engineering) | Ext No. 152 | Jalgaonkar[dot]Kirti[at]icar[dot]org[dot]in |  |

| 3 | Dr. Sheshrao Sakharam Kautkar | Scientist (Agricultural Structures and Process Engineering) | Ext No. 218 | Sheshrao[dot]Kautkar@icar[dot]org[dot]in |

|

| 4 | Dr. (Smt.) Sharmila S. Patil | Scientist (Agricultural Structures & Process

Engineering) Research Interest : Nano Composites, Packaging |

Ext No. 153 | sharmila[dot]patil[at]icar[dot]org[dot]in |

|

Technical Staff

| Sr.No. | Name | Designation | Contact | Photo | |

|---|---|---|---|---|---|

| 1 | Mr.Sutanu Bhuban Mohan Banerjee | Chief Technical Officer | Ext No. 403 | sb[dot]banerjee[at]icar[dot]org[dot]in |

|

| 2 | Mr.Bharat Rajaram Pawar | Chief Technical Officer | Ext No. 409 | br[dot]pawar-icar[at]icar[dot]org[dot]in |  |

| 3 | Mrs.Binu Sunil | Senior Technical Officer | Ext No. 407 | binu[dot]sunil[at]icar[dot]org[dot]in |  |

| 4 | Mr. Prashant Ganpatrao Gavhale | Technical Assistant | Ext No. 404 | prashant[dot]gavhale[at]icar[dot]org[dot]in |

|

| 5 | Mr. Nishant Digamber Kambli | Senior Technical Officer | Ext No. 156 | nd[dot]kambli[at]icar[dot]org[dot]in |

|

| 6 | Mr. Surendra Kashiram Parab | Technical Assistant | Ext No. 404 | sk[dot]parab[at]icar[dot]org[dot]in |

|

| 7 | Kum. Newali S. Pathare | Technician (T-1) | Ext No. 404 | newali[dot]pathare[at]icar[dot]org[dot]in |  |

| 8 | Shri. P. P. Patil | Technician (T-1) | Ext No. 402 | pp[dot]patil[dash]icar[at]icar[dot]org[dot]in |  |

| 9 | Mr. Sohel N. Shaikh | Technician (T-1) | Ext No. | sn[dot]shaikh[at]icar[dot]org[dot]in |  |

| 10 | Mr. Sahil C. Acharekar | Technician (T-1) | Ext No. | sc[dot]acharekar[at]icar[dot]org[dot]in |  |

| 11 | Shri. V. Murugan | Technician (T-1) | Ext no. | v[dot]murugan[at]icar[dot]org[dot].in |  |

Activities of the Quality Evaluation & Improvement Division are functionally classified into various Sections viz. Fibre & Yarn Testing, fabric Comfort and X-Ray & Microscopy. In addition to this there are 6 regional quality evaluation units at Sirsa, Surat, Dharwad, Guntur and Coimbatore.

Fiber Testing Lab

Utility of the cotton fibre is based on fiber quality attributes of the lint. Fiber Testing Lab is engaged in the evaluation of the cotton fiber properties. The main properties of the cotton fibers are length, strength, fineness, maturity and colour. With advent of High Volume Instrument (HVI), testing of cotton fibers have become fully automated. The Fiber Testing lab is equipped with state of the art instruments for quality testing of cotton fibre. At present, this lab is equipped with two High Volume Instruments. The lab is equipped with projection microscopes to determine the fiber maturity.

Yarn and Fabric Testing Lab

Yarn and Fabric Testing lab, existing since 1924 has contributed to the research, quality control and educational activities of the Institute. Main area of activity of this lab is to assess quality parameters of the yarn spun under AICRP on cotton project prior to release of cotton variety. This lab also plays important role Standard Cotton project of the Institute to monitor quality of Standard Cotton Verities. The data generated from this lab on standard cotton varieties showed that there is no deterioration in quality characteristics and spinning performance of standard cottons.

The Yarn Tests Lab is equipped with Lea Tester, Single Yarn Tensile Strength & Elongation Tester, Yarn Evenness Tester, Yarn Twist Tester and Yarn Hairiness Tester. Fabric testing carried out in the Lab include tests such as count of yarns used in a fabric sample, ends and picks, weight per square meter, tensile strength and elongation, tearing strength, bursting strength, abrasion resistance, crease recovery, fabric thickness, fabric drape test and fabric shrinkage test, etc. Facilities to carry out special tests such as single fiber strength and elongation test, moisture content in textile materials, contact angle and surface tension of textile materials, compression test, crush test, three point bending, relaxation / recovery and electrical resistivity of fabric is available in the section.

The laboratory is also equipped with a controlled temperature and humidity unit to study the samples under specific environmental conditions as per the requirement / standards.

Commercial Testing services are provided by the Yarn Testing Lab since 1937. This lab is NABL accredited for important parameters of Yarn and Cloth tests from the year1999 and this facility is widely used by both government and private organizations. Every year training / demonstrations is being organized for the benefit of students, trade and industry.

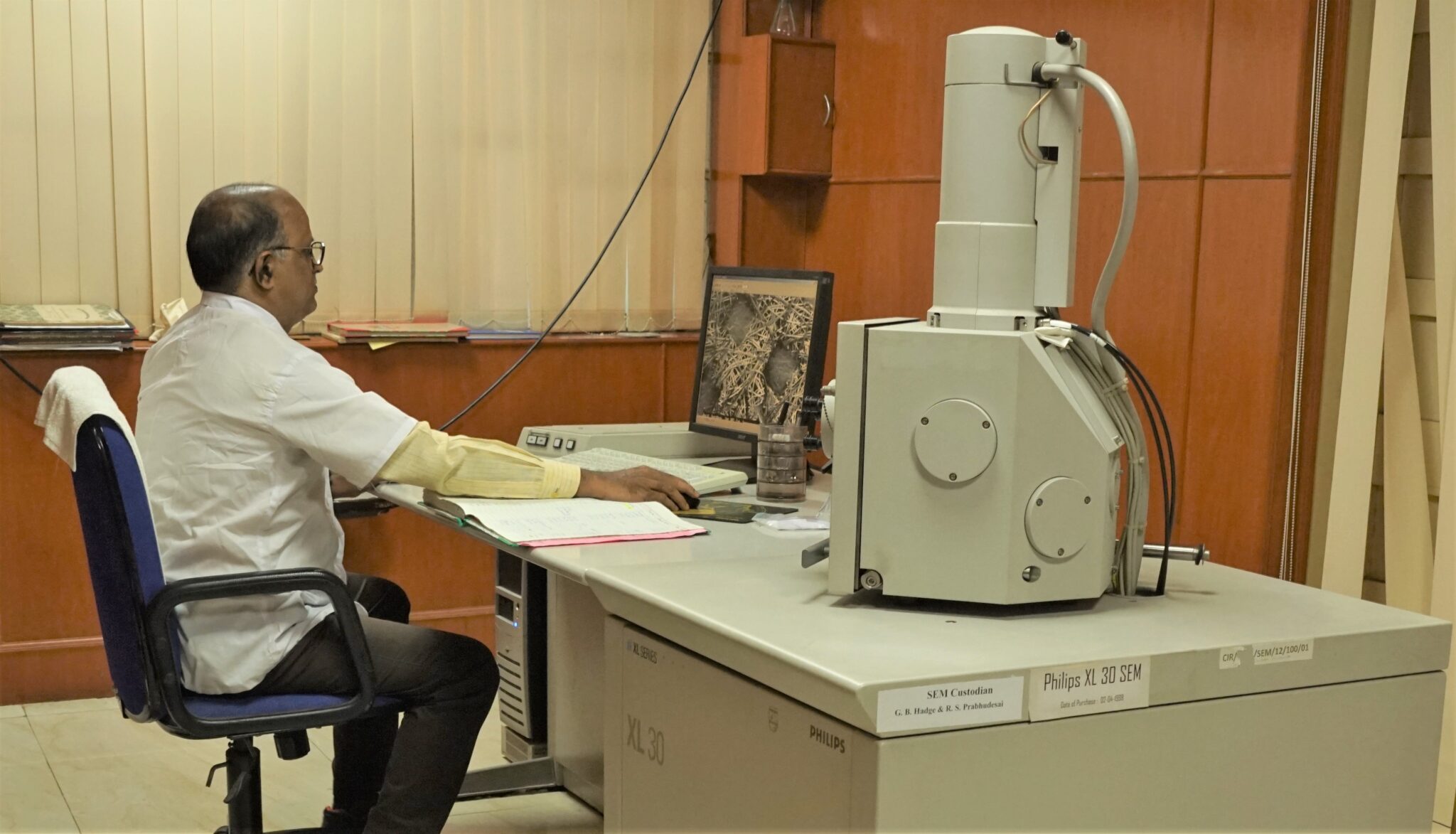

Scanning Electron Microscope (SEM)

ICAR-CIRCOT is equipped with computerized Scanning Electron Microscope (Philips XL – 30) which was purchased from M/S Philips Electron Optics B.V. The Netherland. The instrument is being used for R & D work as well as commercial Testing. Over the years SEM facilities contributed to revenue generation of the Institute through testing of verities of samples from academic Institutes, Students and R & D Laboratories and also utilized as major analytical tool for various research activities.

X-Ray Diffractometer

ICAR-CIRCOT is equipped with computerized PANalytical X’Pert PRO XRD system. The instrument is being used for R & D work as well as commercial Testing. X-ray diffraction techniques are used for the identification of crystalline phases of various materials and the quantitative phase analysis subsequent to the identification. X-ray diffraction techniques are superior in elucidating the three-dimensional atomic structure of crystalline solids. The properties and functions of materials largely depend on the crystal structures. X-ray diffraction techniques have, therefore, been widely used as an indispensable means in materials research, development and production. Over the years XRD facilities contributed to revenue generation of the Institute through testing of verities of samples from academic Institutes, Students and R & D Laboratories and also utilized as major analytical tool for various research activities.

X-Ray Fluorescence Spectrome

ICAR-CIRCOT is equipped with Sequential X-Ray Fluorescence Specrometer PW 1404 which was purchased from M/S Philips, The instrument is being used for R & D work as well as commercial Testing. This X-ray photoelectron spectrometer uses the principles of X-ray spectroscopy to measure the elemental composition of materials. X-ray spectroscopy is a technique that detects and measures photons, or particles of light, that have wavelengths in the X-ray portion of the electromagnetic spectrum. Over the years XRFS facilities contributed to revenue generation of the Institute through testing of verities of samples from academic Institutes, Students and R & D Laboratories and also utilized as major analytical tool for various research activities.

Fabric Comfort Laboratory

Kawabata Evaluation System for Fabrics (KES-FB) refers to a set of one such instrument that simulates several steps followed during subjective evaluation of a fabric such as touching, flexing of the fingers, smoothing, etc. This system comprises 4 instruments which together measure 16 different fabric parameters.The Tensile and Shear Tester (KES-FB 1) assesses the behaviour of fabric under a specific shear and tensile stress in succesion and gives six parameters, viz. tensile energy, linearity, tensile Tensile and Shear Tester with resilience, shear stiffness and hysteresis of hear force at 0.5° and 5° of shear angle. These are designated as WT LT RT, G, 2HG and 2HG5.

The Pure Bending Tester (KES-FB2) evaluates the bending properties of the fabric such a bending rigidity (B) and hysteresis of bending moment (2HB). The Compression Tester (KES-FB3) measure various deformation properties resulting from a continuously increasing compressional force such as compressional energy, linearity of compression and compressional resilience and referred to a WC, LC and RC, respectively.The Surface Tester (KES-FB4) is designed to measure the surface properties. The contactor which picks up the fabric surface is of a special design that simulates the human fingertip and the measurement is made to closely resemble the (hand) touch of a fabric. Surface tester measures frictional coefficient, deviations in frictional coefficient and the geometrical roughness of fabric surface. These are expressed respectively as MIU, MMD and SMD.

How to handle value assessed?

Fabric properties such as tensile, shear, bending, compression, surface friction and geometrical roughness are measured by KES-FB and used along with fabric structure (weight and thickness) to arrive at primary hand values (PHV) by using appropriate transformation equations evolved for defined end use of a fabric. PHV values are, in turn, used to predict the total hand value (THV) employing a second set of conversion equations. While PHV can range from O to 10 the THV lies in a scale of O to 5 (not useful to excellent). PHV quantifies subjective feelings like stiffness, crispness, fullness and softness, and smoothness and the overall handle of a fabric is shown by THV.

Thermal Properties

Thermal properties of fabrics are one of the most important features of textiles. The most important thermal properties of a fabric are thermal insulation, thermal conductivity and Q-max (warm/cool feeling). Thermolab II is a precision instrument for calculating thermal properties.

Moisture management test (MMT)

The MMT (Moisture Management Tester) is useful for the measurement, evaluation and classification of liquid moisture management properties of textile fabrics. The MMT was developed to measure dynamic liquid transport properties of knit and woven fabrics in three dimensions.

All India Co-ordinated Research Project on Cotton (AICRP on Cotton)

In view of the importance of quality evaluation in development of new strains, considerable work has been carried out at ICAR-CIRCOT onvarious aspects of quality evaluation such as ginning performance, fibre characteristics, spinning performance and yarn quality, etc. This has involved designing of new instruments and equipment, evaluation of new equipment developed by other organisations, standardisation of testing methods, development of new testing procedures, etc. To meet the demand for cotton by various sectors, improving quality is as important as increasing productivity. ICAR-CIRCOT has been co-ordinating all technological work connected with the AICRP on cotton intended to bring about continuous improvement in quality and production of cotton in the country. Under the AICRP on cotton, the breeding material from cotton breeders of various states is systematically screened every year for fibre quality, yield and pest resistance. Promising genotypes are subjected to further trials.

The Institute evaluates fibre quality of several thousand samples required to be screened prior to identifying a variety, which is superior to an existing one. The process is repeated for a few years and spinning tests are also conducted at the Institute for samples of advanced trials to ensure that the variety when released is suitable for hassle-free processing. The results of tests on samples received under AICRP on cotton are issued as reports to the concerned agricultural scientists. Some of the reports are discussed at the Zonal and All India Workshops and advice is given by ICAR-CIRCOT scientists to the breeders on the improvements desired in respect of fibre characteristics. Further, whenever desired, norms are suggested for adoption during selection of the material. Every year a Committee known as "Varietal Release Committee" carries out the task of releasing new varieties. Director, ICAR-CIRCOT as a member of this Committee plays a dominant role as far as the Quality aspect of the variety concerned. ICAR-CIRCOT is playing and would continue to play a significant role in the development and release of varieties with fibre properties that meet the demands of the user industry. Being strategically placed, ICAR-CIRCOT through mill surveys finds out the projected mill requirement of cotton and advises the breeders who in turn reorient their breeding priorities.

Calibration Cotton Standards for High Volume Instrument

It is well known that the fibre quality assessment through objective measurement of fibre attributes is carried out using state-of-the-art instruments like the High Volume Instrumentation System that need calibration using what are known as "Calibration Cottons" the Standard Reference Materials. Till 1997, the United States Department of Agriculture (USDA) was the only accredited agency qualified to produce these reference materials. Import of calibration cottons involves time, foreign exchange and arduous procedural wrangles for import.

The circumstances that led to CIRCOT’s preparation and supply of calibration cotton during late nineties to the textile industry in India are now part of history. With USDA discontinuing its supply of ICC mode calibration cottons, under an ICAR Revolving Fund Project, the Institute embarked itself on an exciting programme of making available this reference material for the industry. Two sets of standards one for conventional instruments and the other for HVI are being produced and marketed under this programme. The novelty of the CIRCOT HVI standards is that the same calibration cottons are useful for both ICC and HVI mode operation.The Institute has been able to create a customer base of more than 350 users who seem to be satisfied with both the quality and service as gauged by their repeat orders. With years of experience in preparation of calibration cotton, ICAR-CIRCOT has developed a processing flow chart and screening procedure for preparation of calibration cotton within acceptable standard and tolerance limits.

As USDA, discontinuing the supply of ICC mode calibration standards for HVI, ICAR-CIRCOT embarked on a programme through YT section of producing and marketing calibration cotton standards since 1997, for ICC & HVI mode operations. The traceability of ICAR-CIRCOT"Calibration cotton" is close to the USDA standards, it means that, if we calibrate an HVI of any make using USDA calibration cotton standards or ICAR-CIRCOT Calibration cotton standards and make measurements for unknown cotton, the results will be unaffected. ICAR-CIRCOT Calibration Cotton programme has been a success by all standards. The Institute has been able to create a customer base of more than 250 users who seem to be satisfied with both the quality and service as gauged by their repeat orders.

Cotton Value Chain

Project entitled "A value chain for Cotton Fibre, Seed and Stalk: An Innovation for Higher Economic Returns to Farmers and Allied Stake Holders", funded by the World Bank through the National Agricultural Innovation Project (NAIP) of the Indian Council of Agricultural Research (ICAR), The project was in consortium mode with Central Institute for Research on Cotton Technology (CIRCOT), Mumbai as lead centre and Central Institute for Cotton Research (CICR), Nagpur, Super Spinning Mill Ltd., Coimbatore as consortium partners. In addition, many government agencies, NGOs, private industries were involved in carrying out work related to the project.

Under the project an attempt was made to resolve the issues related to the value chain from farmer’s field to final product development with the following objectives.

- To grow established cotton genotypes in the adopted villages with integrated production technology practices.

- To reduce the level of contaminants in cotton by adopting appropriate on-farm and off farm management practices and to label cotton bales with fibre attributes after appropriate ginning.

- To prepare yarn, fabrics and garments in the modern mill and to manufacture eco-friendly textiles in handloom sector by employing CIRCOT technology for bio-scouring and natural dyes.

- To ensure additional income to farmers and alternate raw material for industry by establishing cotton stalks supply chain to board / briquetting industries.

- To demonstrate innovative scientific processing of cotton seed for oil extraction.

- Back to previous page

- |

-

Page last updated date:01-12-2025 10:32 AM