Technologies Commercialized

Salient features

• Consists of 4-6 spiked cylinder and grid bars

• Cleaning occurs due to rotational motion of cylinders and agitation of cottonseed across grid bars

• Capacity: 3.5 – 6 tonnes/h

• Cleaning Efficiency 30-40%

Salient Features

Comprises of leather roller, fixed knife, moving knife, seed grid and feeder

Power: Electric motor of 0.75 kW (Single Phase)

Capacity:

Lilliput Gin: 4-5 kg seed cotton / h

CLOY Gin: 7-8 kg seed cotton / h

HIPRO (High Production) gin: 19-21 kg seed cotton/ h

Salient Features

System comprises of centrifugal trash fan, cyclone, ducting and compactor

Capacity: 2.5 tons of trash per hour

Mortality rate of PBW larva and pupae: 100%

Power: 21 HP

Salient Features

Roller made with nitrile rubber having radial layers of softer rubber compound to form grooves

Comprises of three parts viz. inner hard core, outer ginning body and soft groove area

Optimum roller speed: 40 rpm

DR gin output: Lint output with self-grooving rubber roller is about 25-30% higher than conventional leather roller

Three times more durable than conventional leather roller

Salient Features

Direct heating type ‘Cottonseed Dryer’

Online drying of cottonseeds in cotton ginneries/ oil mills

Capacity: 5-7 TPH

Heat capacity: 9-12 lakh kcal/kg

Dryer is capable to bring down the moisture content from 40% to 9-10% i.e., optimum moisture required for oil expelling

Energy efficient compact drying system

Salient Features

Consists of a compact trapezoidal shaped cage

Forced draft aeration system for supply of air for rapid initiation of fire and for enhanced combustion process

Requires only 200 kg of biomass briquettes as against 300 kg of fire wood in traditional cremations

Use of kerosene is completely eliminated

Requires only 2 kg camphor against 5 kg camphor and 10 litres in conventional crematoriums

Cost per cremation with ICAR-CIRCOT Green Crematorium is Rs 2500/- as against Rs. 5500/- with conventional crematorium. Around 55% of cost saving per cremation is attained which makes it economical

Salient Features

Stove can handle pellets with 6-8% ash content

Stove has provision for removal of ashes while in operation

Pellet utilization capacity of stove is 6-8 kg /h

Salient Features

Cotton-based electrically conductive yarns were developed which can be stitched over any fabric

Maximum heat generation of 50°C can be achieved within 15 seconds by using 5 to 12 volt DC power supply/ any rechargeable power bank

Safety concerns are addressed by giving water repellent and flame retardant treatments to textiles to avoid water permeability and short circuit fire

Salient Features

Output capacity: 100 g/h (cotton sample)

Manpower: Two (One skilled and one semi - skilled)

Power: Single phase, 0.6 kW motor (for miniature carding, miniature draw frame) and 1kW (for miniature sliver to yarn spinner)

Controlled movement of fibres during processing enables faster processing and production of quality yarn.

Pneumatic suction systems have been incorporated in the ring frame, rotor spinner and carding machine and in licker-in zone for collection of broken ends/ droppings.

Machines are fitted with safety and emergency stop switches

Description and Salient Features

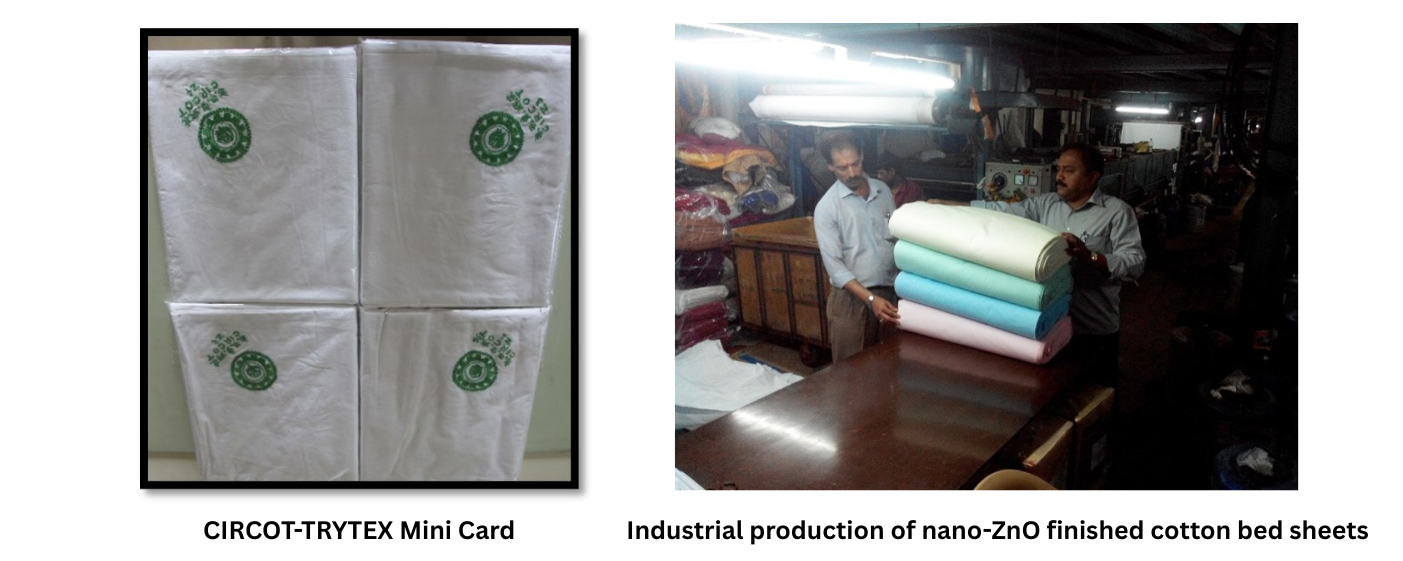

ICAR-CIRCOT has developed a novel process of using zinc-based nano finishing on cotton bedsheets for durable antimicrobial finish. The ICAR-CIRCOT antimicrobial bed sheets provide an added layer of protection against cross-contamination for patients and healthcare providers. The excellent performance of antimicrobial properties of the bedsheets while in use and after wash were demonstrated at the All India Institute of Physical Medicine and Rehabilitation, Mumbai, which is an apex Institute under the Ministry of Health and Family Welfare, Government of India. These bed sheets are made from 100% cotton fabric and nanofinished by imparting antimicrobial treatment with zinc-based active ingredient showing inhibition of bacterial growth by more than 99% in laboratory tests against two representative pathogens, Klebsiella pneumoniae and Staphylococcus aureus even after 50 wash cycles and also show efficient blocking of Ultra Violet (UV) radiation with UPF of 50+

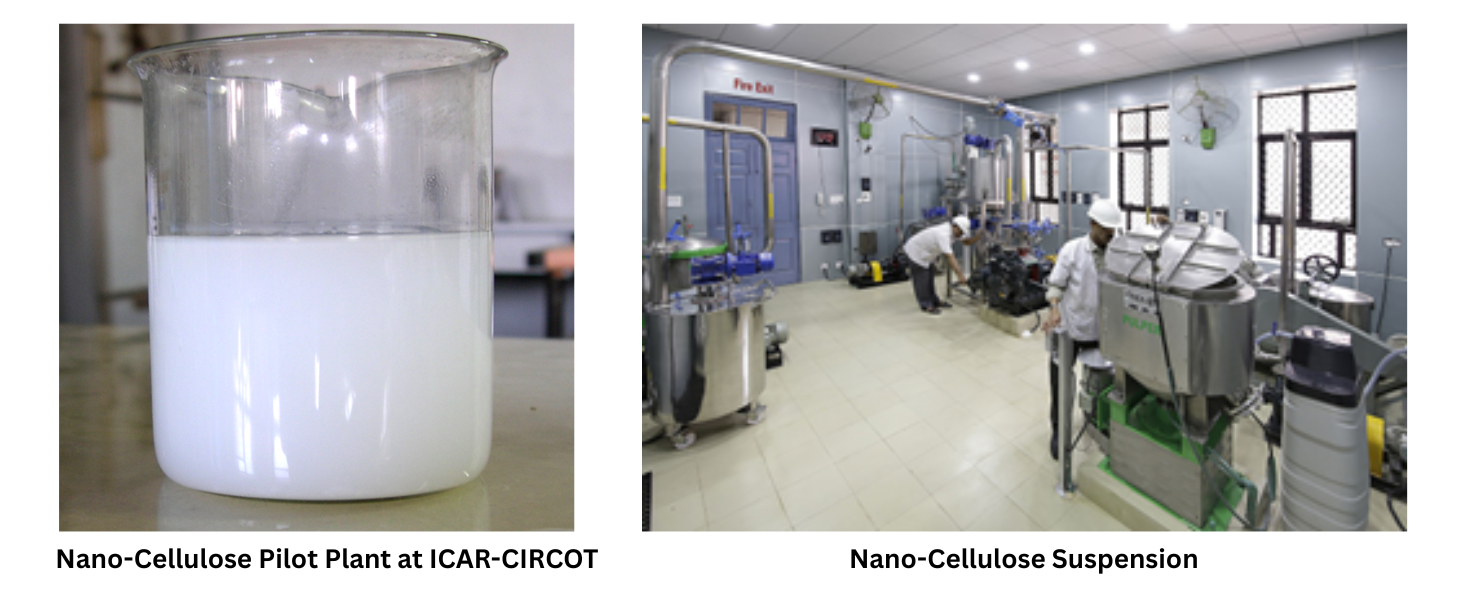

Description and Salient Features

ICAR-CIRCOT has developed process protocol for the preparation of nano-cellulose from cotton linters and cotton wastes by novel and energy-efficient chemo-mechanical process and has obtained three process patents. Through funds from NAIP, established nano-cellulose pilot plant at ICAR-CIRCOT, Mumbai, with a capacity of 10 kg per shift of 8 hours. This is a first of its kind in India and unique in the World that can use cotton linters as the raw material. The objectives of nano-cellulose pilot plant is to demonstrate ICAR-CIRCOT’s technology to various stakeholders for product development, technology incubation and licensing.

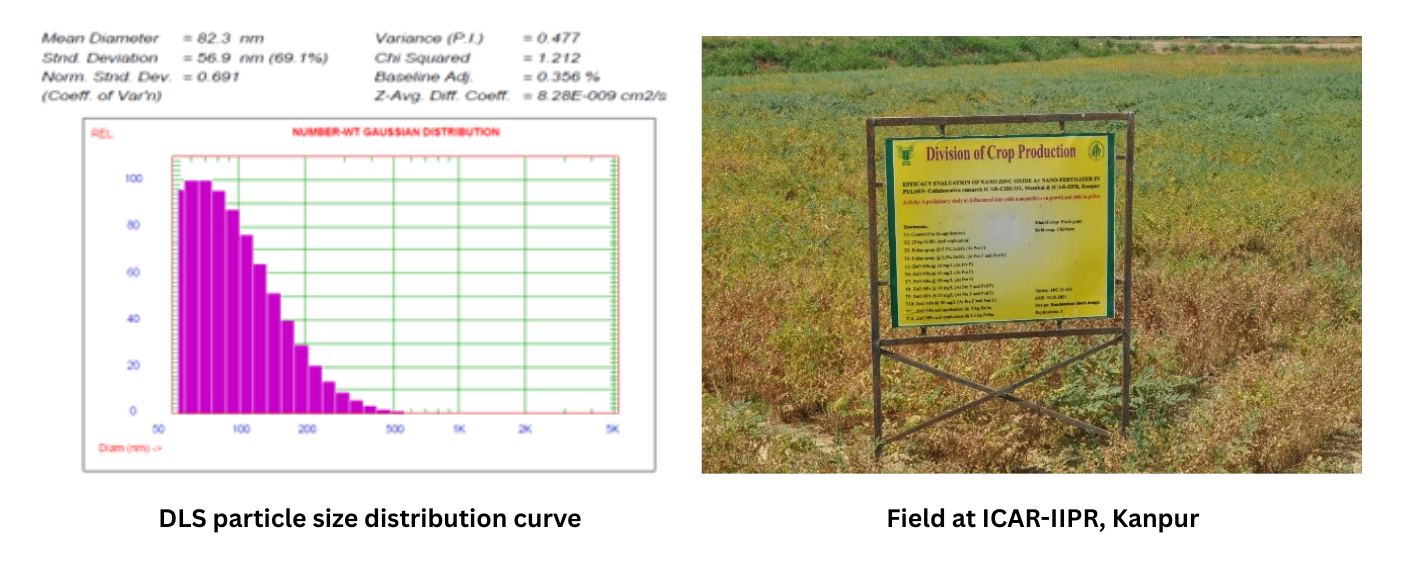

Description and Salient Features

The nano-zinc suspension is prepared by a novel chemical process with polymeric capping agent to make it a stable suspension. The average size of nano-Zinc particle is 82.0 ± 10 nm as analysed by DLS nanoparticle size analyser. The zeta potential is +25mV as analysed by DLS electrophoretic technique. Using this nano-zinc suspension, an increase in grain yield of 30% was reported in chick pea grown in sandy soil, by ICAR-IIPR, Kanpur. Also, the zinc fertilizer requirement could be reduced to the level of 75% in dryland paddy and fodder maize as reported by ICAR-NIASM, Baramati. The pot culture study and field trials were conducted during the years 2021-2023.

Description and Salient Features

ICAR-CIRCOT has developed novel protocols for production of moulded kitchen dishware from banana pseudostem fibres. The fibres are extracted from pseudostem, pulped and sheets are formed. Required shapes were achieved using the various mould designs by hot pressing method. ICAR-CIRCOT technology for pulping of banana pseudostem followed by thermoforming, using a custom-designed mould, produces small sized kitchen dishwares with required strength and finish. The advantage in this process is high yield and simplified protocol, amenable for scaling up. Also, banana pseudostem fibres along with bio-degradable glues were used for the production of wall panel boards.

Description and Salient Features

A novel chemical process for production of nano-ZnO using soluble starch as stabilizer for use in cotton textiles to impart antibacterial property was developed by the Institute in the year 2006. Later on, the same material was also demonstrated for its use as fertilizer for field crops. M/s. RCF, Mumbai, evaluated its potential application in agriculture as fertilizer in the year 2016. The developed process is a simple procedure without involving any toxic chemical use and is easily amenable for scaling up. Also, the effluent from this process could be treated using the conventional effluent treatment system.

- Back to previous page

- |

-

Page last updated date:07-11-2025 03:02 PM