Nano-cellulose Impregnated Starch-based Biodegradable Packaging Films

Description and Salient Features of Technology :

Nano-cellulose (NC) synthesized from cotton linters was used as a green filler in starch matrix to obtain composite films with improved functionality. The films were prepared using solvent casting method. Film formulation was optimized using a response surface methodology (RSM) tool. Easily heat sealable stand-alone films with average 100 μm thicknesses were prepared using the optimized formulation.

- The incorporation of NC (0.89%) to starch polymer yielded films with improved mechanical strength, flexibility and water vapour barrier.

- Tensile strength (TS), elongation at break (EB), water vapour permeability (WVP), bursting strength (BS) and tearing strength (TeS) of the films was found to be 8.92 MPa, 41.92%, 7.07x10-10g/m.s.Pa, 556 kPa, 354 mN respectively.

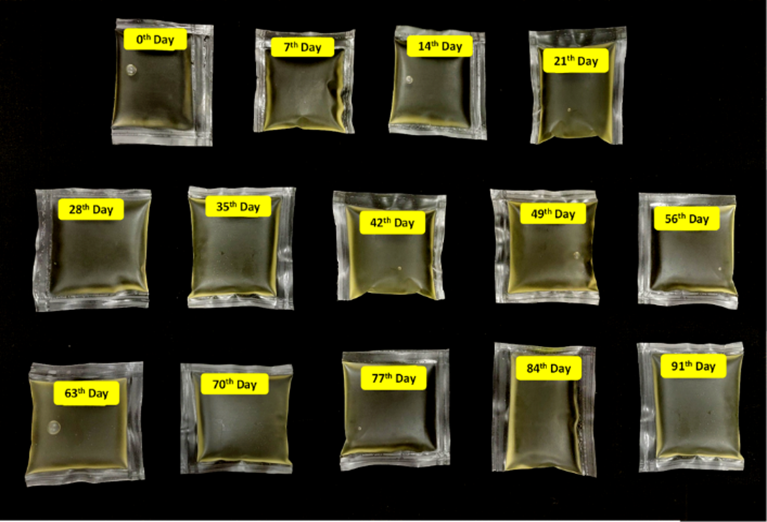

- The films presented high effectiveness in keeping the quality of edible oil for more than 3 months at ambient storage conditions.

- Soil burial test showed complete degradation of films within four weeks.

- These NC impregnated starch films have promising potential as an eco-friendly packaging material alternative to synthetic polymers.

Stakeholders : Packaging industries, Plastic manufactures

Benefit to Stakeholders :

- Improved mechanical and barrier performance

- Cost effective technology as starch is a very cheap material and abundantly available

- Films are eco-friendly alternative to synthetic packaging materials. This in long run will help to mitigate the biggest challenge of plastic waste-disposal faced by packaging industries.

Cost :

The cost of commercially available synthetic polymeric films is about 180-200 Rs./kg. The cost of developed biodegradable starch-NC films on mass scale production is expected to be the same as the commercial plastic films.

- Back to previous page

- |

-

Page last updated date:20-11-2025 03:22 PM