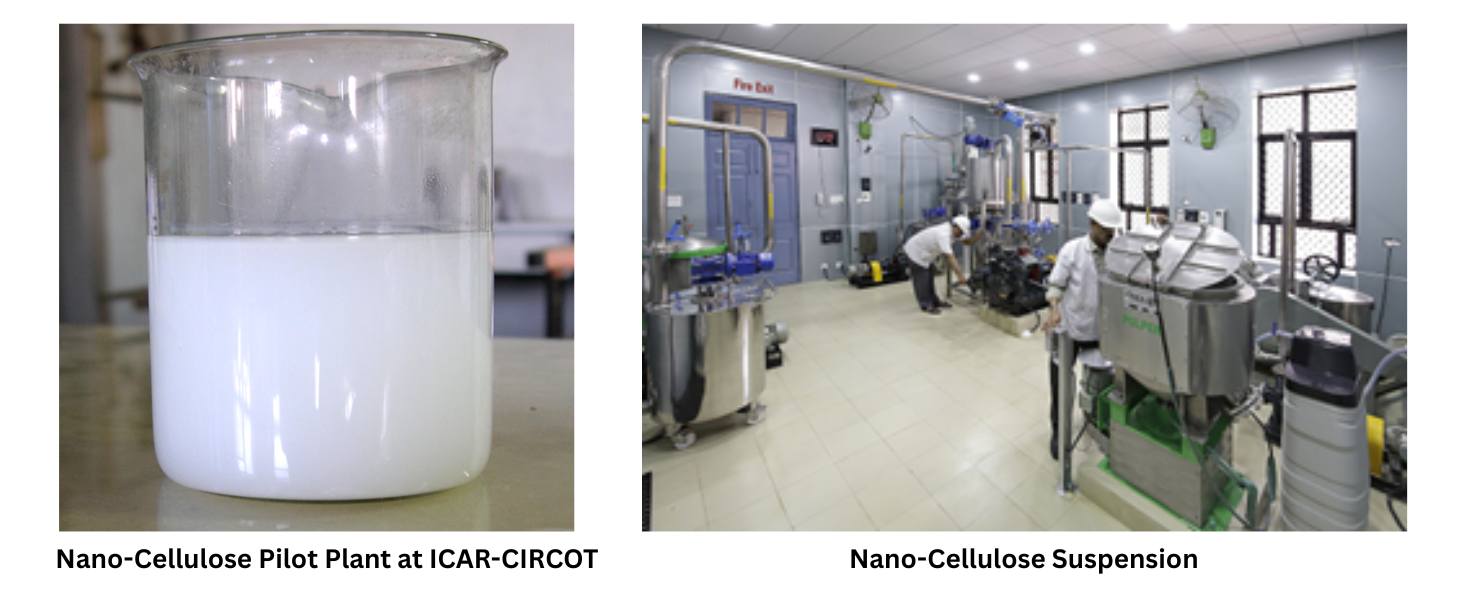

Production of Nano-cellulose from Cotton Linters

Description :

ICAR-CIRCOT has developed process protocol for the preparation of nano-cellulose from cotton linters and cotton wastes by novel and energy-efficient chemo-mechanical process and has obtained three process patents. Through funds from NAIP, established nano-cellulose pilot plant at ICAR-CIRCOT, Mumbai, with a capacity of 10 kg per shift of 8 hours. This is a first of its kind in India and unique in the World that can use cotton linters as the raw material. The objectives of nano-cellulose pilot plant is to demonstrate ICAR-CIRCOT’s technology to various stakeholders for product development, technology incubation and licensing.

Stakeholders :

Cotton growing farmers, Ginning industries, Paper industries, Spinning industries, Cement industries, Packaging industries and Paint industries

Benefit to Stakeholders :

- Nano-cellulose (1%) reinforced starch film used to pack strawberry and broccoli is 100% biodegradable, enhanced strength (3 times) and reduced oxygen permeability (2 times) when compared to that of control starch films

- Nano-cellulose as fillers in concrete (@1%) reduced the curing and setting time from 3 weeks to 2 weeks due to its very high water holding capacity

- Nano-cellulose act as a shear thinning agent in water based paints

- Nano-cellulose based formulation is used as lubricant to improve the spinning potential of cotton fibre. The developed formulation is 42% efficient than the commercial product in terms of reducing the yarn breaks during spinning and also, does not impart oily feel during the mixing process

Cost/Benefit Cost Ratio :

Production capacity : 10 kg per day

Break-even point : 24 months

Cost of production : Rs. 7,000 per kg (solid basis)

Selling price : Rs. 10,000 per kg (solid basis)

Net profit ratio : 30 %

ROI : 23 %

Status of commercialisation :

Product development using Nano-cellulose is being carried out in collaboration with following parties:

- M/s. Godavari refineries, Mumbai

- M/s. TKML, Coimbatore

- M/s. Lafarge Industries, Mumbai

- M/s. Asian Paints, Mumbai

- M/s. Biofac Inputs Pvt Ltd., Hyderabad

- पिछले पृष्ठ पर जाने के लिए

- |

-

पृष्ठ अंतिम अद्यतन तिथि:20-11-2025 11:47 पु