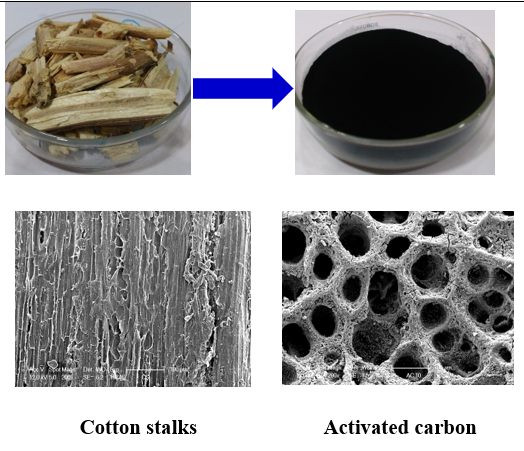

Production of Activated Carbon from Cotton Stalk

Description and Salient Features :

At present cotton growing farmers are burning the cotton stalks in the field itself. The technology gives an alternative solution for cotton growing farmers for utilization of cotton crop wastes and converting it into activated carbon. Activated carbons are known to work as very effective adsorbents due to their highly developed porosity, large surface area, surface active sites and reactivity. However, due to high production cost, as these are commercially produced from coals, these materials tend to be more expensive. Therefore, ICAR-CIRCOT has developed process protocol for converting cottons stalks into activated carbon by chemical soaking followed by thermal degradation method.

Salient features

- Surface area (BET) : 1010m2/g

- Average pore radius : 2.67808e+01Å

- Total pore volume : 1.353e+00 cc/g

- Bulk density : 0.4566 g/mL

- pHpzc : 4.6

Stakeholders : Carbon manufacturers, Small and large scale textile and technical textile industries

Benefit to Stakeholders :

- Yield of activated carbon from cotton stalks is around 40%.

- One kg of cotton stalk can produce 400 grams of activated carbon

- Technology would help in generation of additional income to cotton growing farmers and improve the soil health by avoiding burning of the cotton stalks in the field.

- Avoids burning of cotton stalks in the field itself and reduces the greenhouse gases emission

Cost : Lab scale production cost of activated carbon from cotton stalks is Rs.440 per kg.

- पिछले पृष्ठ पर जाने के लिए

- |

-

पृष्ठ अंतिम अद्यतन तिथि:20-11-2025 03:26 PM